Restoration projects

Posted on September 21st, 2012

Restoration projects

creating functional classics

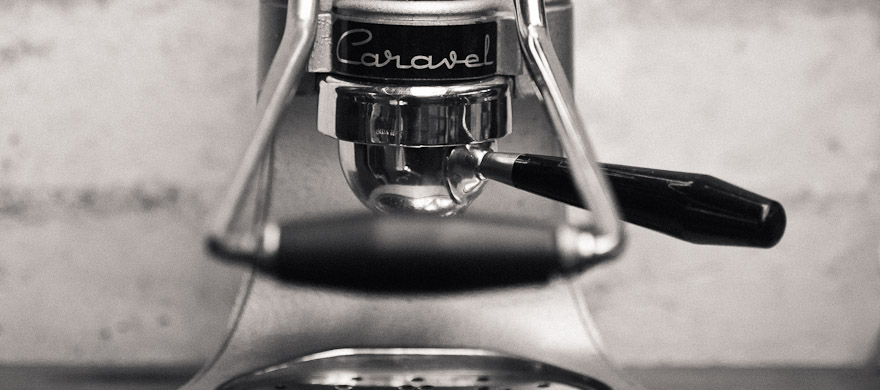

It could be argued that espresso machine design reached it’s peak in the workshops and foundries of northern Italy in the mid 20th century, and everything since then has been a bit boring! There’s a certain character about machines of that era that just exude flair, passion and artistry. And while not many of us are lucky enough to own a Gaggia Esportazione, Cimbali GranLuce, La Pavoni Concorso, La San Marco Lollobrigida or Faema Urania, it’s certainly true that any vintage coffee machine is eminently restorable to perfect working condition given enough love and attention.

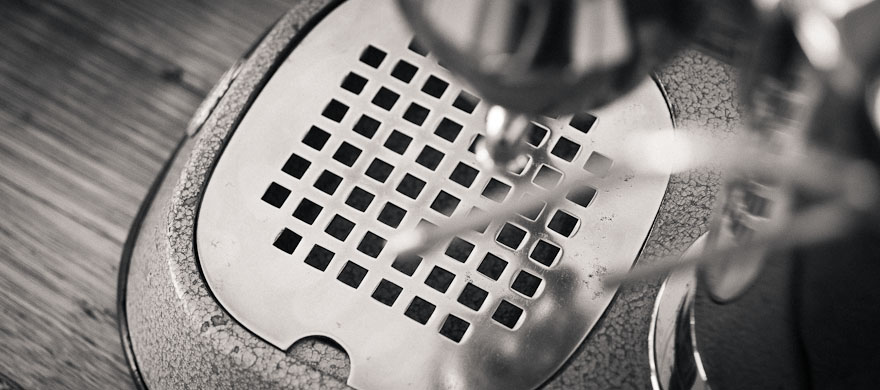

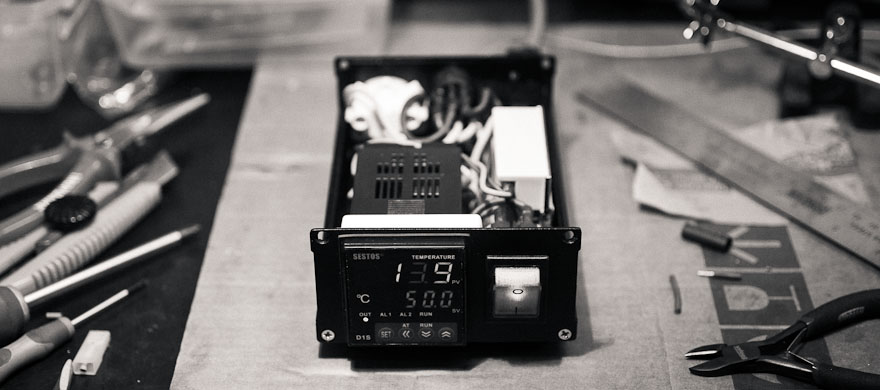

Whether you’ve got an older second hand machine that you want to bring up to scratch for domestic or cafe use, or you’ve uncovered a gem in a forgotten corner of the garage, I can help you with either a complete restoration from start to finish, or a particular aspect if you’re doing most of the work yourself. My aim with restorations is always function before aesthetics – what’s the point having a shiny beautiful machine if it makes rubbish coffee or no coffee at all. After that, anything is possible including installing modern electrical systems, re-plating or re-manufacturing worn parts, re-spraying paintwork and reproducing original factory artwork. My preference and advice is always to preserve original finishes where possible, as this preserves character and adds value to the machine in the long term.

Naturally these hands-on processes can be very time consuming, and I assess and quote each restoration project as a flat labour fee plus expenses, according to the result you want to achieve.