SOLD – Conti Prestina

Posted on November 23rd, 2014

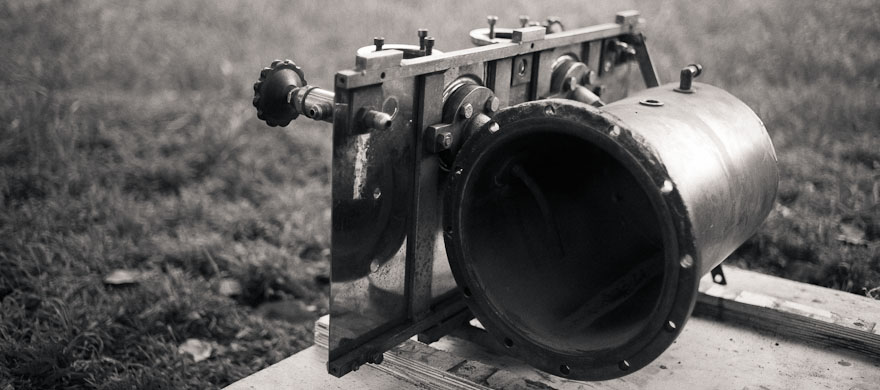

Conti Prestina

single group lever machine

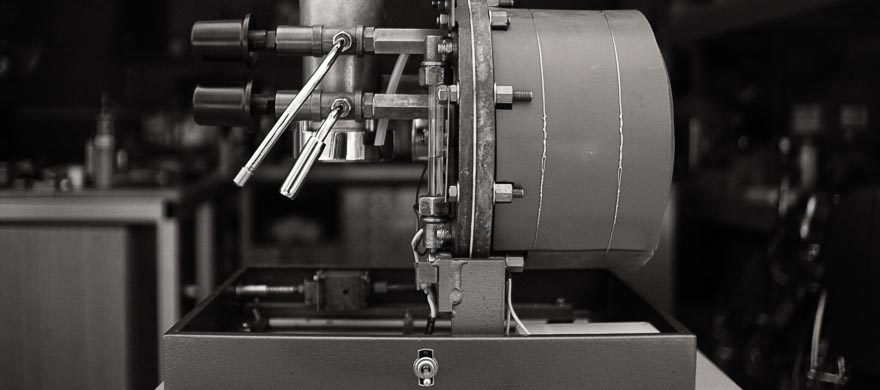

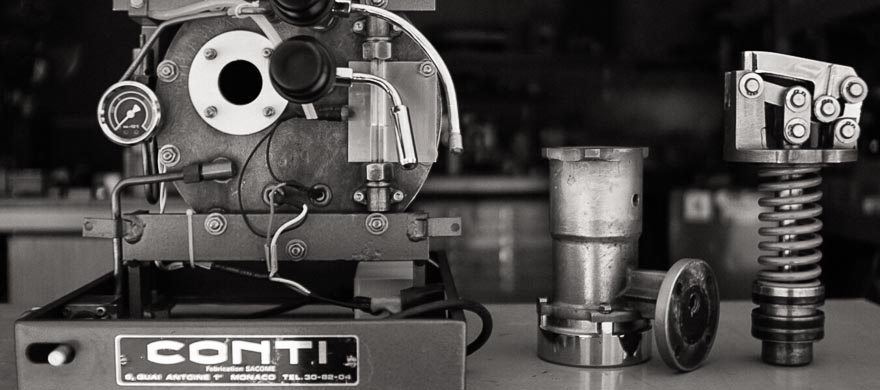

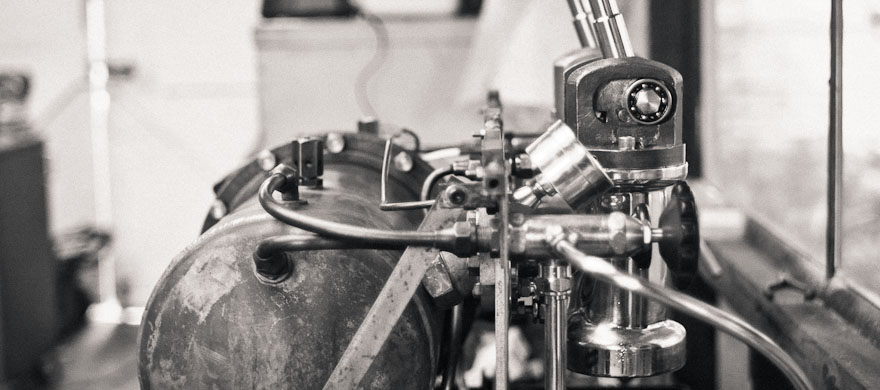

For sale is my Conti Prestina single group lever machine, fully restored. These machines are very rare in Australia and is the only one I have ever seen. The Conti group is unique, using a series of linkages to convert the lever action to a vertical piston movement. This machine has an incredibly small footprint for it’s capability and boiler volume, Conti used an innovative compact construction to place all the necessary components on the massive boiler flange.

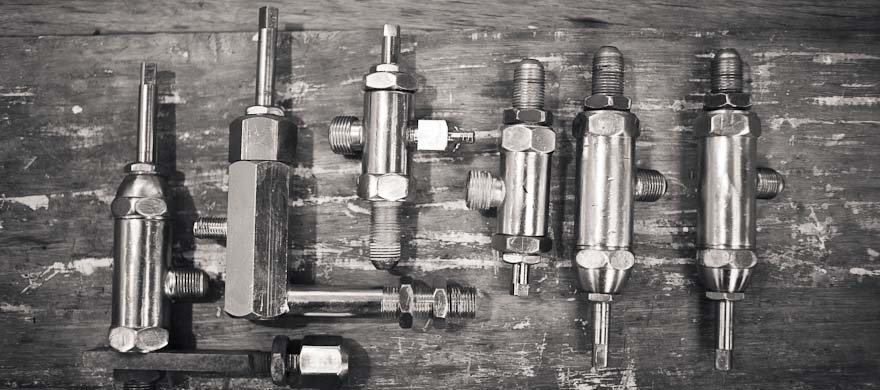

This machine has been rebuilt from the ground up with OEM parts sourced directly from Conti in Monaco, who still make spares for the group. Replaced parts include the group spring, pressurestat, wiring, silicone boiler insulation, nuts and bolts where mild steel was used, and all gaskets and seals.

Operationally the machine is in perfect condition, and cosmetic condition is excellent. There are a few spots where the protective lacquer is lifting off the brass plated panels, and a few minor blemishes in the front panel and base.

This is a 10 amp (standard household power) machine and requires a plumbed mains water supply or flo-jet pump.

Price: $2,900 including GST.