This machine makes a badass noise

Posted on November 6th, 2016

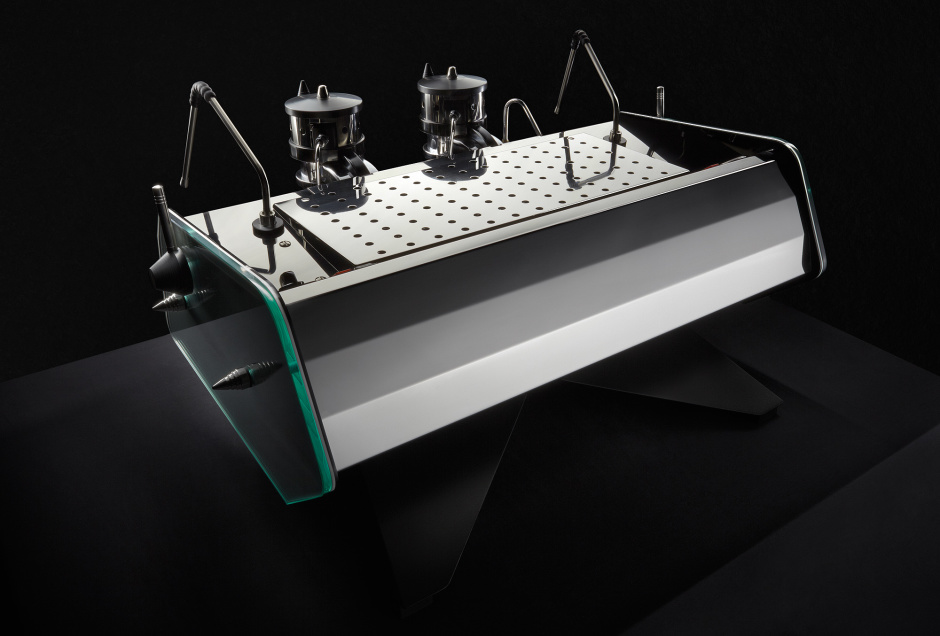

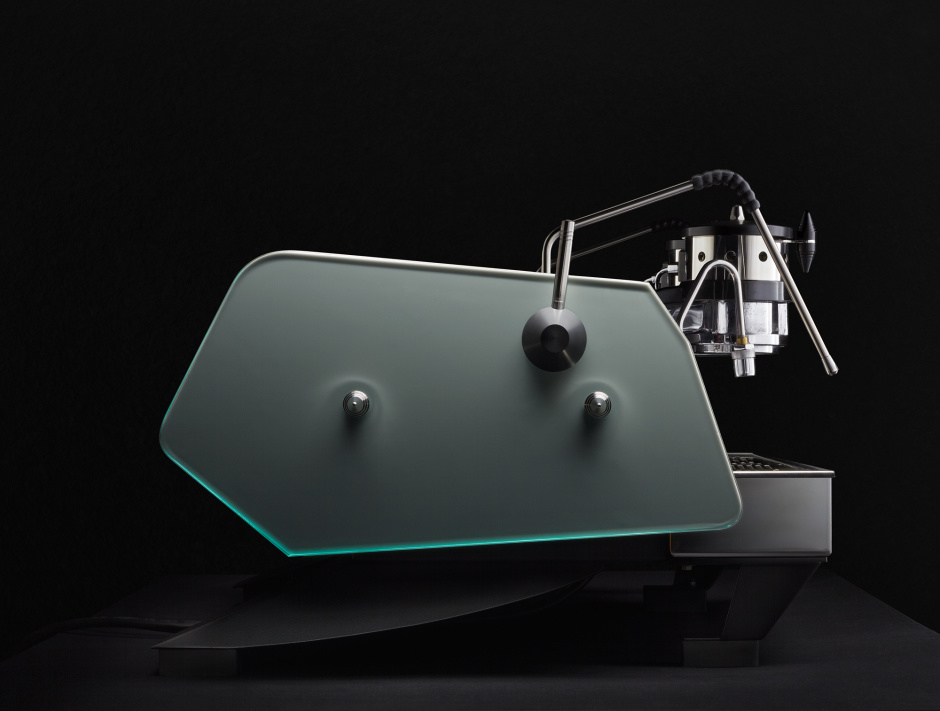

This machine makes a badass noise #keesvanderwesten #mistral #custom #pierobambi #coffeemachinist

This machine makes a badass noise #keesvanderwesten #mistral #custom #pierobambi #coffeemachinist

The underbelly. The two red displays are the group cap heaters, running cooler than the brew boiler internal temperature on the right but keeping each group locked down. Very happy with this mod, @gonzlab will be firing it up for Casati’s real soon. #keesvanderwesten #mistral #custom #pierobambi #coffeemachinist

Time to bid farewell to this guy. Part San Marco, part Victoria Arduino lever, much custom, wow. Details up on the website now, link in bio. Please consider. #lever #espressomachine #custom #coffeemachinist

enabling the true function of the Manual Paddle

As usual, there are aspects of any piece of equipment that can be improved. My main gripe with the Linea Mini is that as standard, the paddle switch is not a ‘real’ paddle switch.

Let me explain – the original MP ‘mechanical paddle’ group is much loved by baristas for the control it allows over the pre-infusion phase of espresso brewing. The mechanical nature of the group allows the water flow to be turned on first at a lower, or ‘line’ pressure – this is simply the water pressure present in the mains and through the boiler/group, usually around 3 Bar. When the paddle reaches the end of it’s travel, the pump is engaged, and full brewing pressure (around 9 bar) is applied to the coffee. This two stage operation allows a skilled barista to perfect each shot by allowing the most critical first stage, where we want an even saturation of the coffee bed, to happen at a lower pressure. This improves the chances of the coffee puck saturating evenly, giving us a tastier shot.

So, a Mechanical Paddle group is a good thing in terms of control, but, being mechanical, there is a down side. It’s relatively complex to make and thus expensive, and, requires fairly regular replacement of o-ring seals. La Marzocco chose to fit a paddle switch to the Linea Mini, but the important distinction here is that it does not operate a mechanical valve, but a single microswitch which engages the water flow and the pump, practically simultaneously. Thus, the ethos of the paddle is lost because there is no first stage. It doesn’t matter how you move it, quickly or slowly, the result is the same. All this is not to say that it doesn’t work – clearly it does, and well, we just lose out on control over the infusion process. Perhaps La Marzocco chose this for reasons of simplicity – my argument would be all well and good, but if there is a paddle switch present, the expectation is that it works like a real one.

Well, we can make that happen! On the pump outlet I’ve added an extra solenoid with an adjustable needle valve, that is switched on as soon as the paddle is out of it’s stop position. This allows the first stage of the paddle’s movement to replicate the line pressure stage of a mechanical paddle group. In fact, the pressure can be set internally by adjusting the needle valve setting to give whatever pressure is desired for the pre-infusion phase.

Then when the standard microswitch is engaged mid-way through the travel, the bypass solenoid is switched off and the pump comes to full pressure. In addition I’ve added a spring loaded pre-infusion cylinder to the group to further soften out the pressure ramp-up and decline. The group pressure control ends up being a hybrid of Slayer, Kees van der Westen Speedster and La Marzocco Mechanical Paddle – with the best of all worlds. All electric, no seals to replace and fully adjustable. I’m very happy with the result!

Summary of the modification:

At this stage the installed modification is only available for machines brought to my workshop, and there are no plans to distribute a kit as modifications of factory parts, plumbing and electrical connections are required. If you are confident to handle this work as a DIY install, please contact me for pricing and availability. Alternatively you could contact a trusted technician local to you to perform the install work with my instructions. The modification is available for both 230V and 110V machines.

Kees van der Westen

Custom fit Coffeelab tamper

One often-overlooked ingredient to good espresso preparation at home is use of a quality tamper. In that regard, it’s hard to go past the Australian-designed and made Coffeelab, it really is a thing of beauty – the materials, design and feel of the finished object are top notch.

The crucial thing that is hard to achieve with an off-the-shelf tamper is a good fit to the basket to ensure an even tamp, and in this case Aaron was looking to improve the match of his existing base to the 54.5mm baskets of his La Spaziale. I was able to help by sourcing a new 58mm base directly from Coffeelab, and re-machining the diameter to provide an exact fit.

The result was a perfect fit, without changing the ergonomics or appearance of a design that Aaron already loved. Sweet!

Single boiler domestic machine

I bought this little Salda for $10 at a garage sale, knowing it would be a good little machine with a service and a few minor improvements.

As standard, single boiler machines including the Rancilio Silvia, Gaggia Classic, Lelit, Nemox, Imat, Quaha and others are perfectly capable of making good espresso though with a few downsides, one of which is a huge variance in boiler water temperature due to their very simple thermostats. This can be compensated for in a few ways, one popular option being to retrofit a PID controller to help regulate boiler temperature more precisely, which is one key ingredient to making consistently good espresso.

This is a rather expensive and complicated option (although PID hardware itself is not costly these days – it’s the installation and calibration that can be tricky), and a simpler, more cost-effective modification can be to simply fit a digital thermometer to the boiler giving the user a visual indication of the boiler temperature, which can then be used to time the start of the espresso extraction for the best results. This is known as Temperature Surfing.

Improvements included:

I ended up taking things a bit further than I’d initially planned, but I reckon this is now the best little single boiler machine around, and makes killer shots with a bit of careful attention to the brewing temperature and pressure. As it’s so simple and small, this is the perfect machine to chuck in the boot with a hand grinder for a weekend away.

Commercial conical grinder

I picked up this grinder as a fixer-upper, there was a sad story from the previous owner which involved attempting to grind the stainless steel bolt that holds down the central burr blade. Roburs have big strong motors and reduction gearboxes, so this was enough to bend the shaft that holds the burr, leaving a non-functional grinder making very nasty crunchy noises.

To fix it, the entire grinder was disassembled and the gearbox shaft painstakingly straightened and re-machined to perfect alignment. It would have been far easier to replace that part, but they are not stocked in Australia so a replacement was very costly and months away by boat.

While I was there, I did the following mods:

This is now my workshop grinder, and I’m pleased with the mods. The dial indicator makes it really easy to swap back and forth between filter and espresso grinds with a high degree of precision.

bespoke additions for your machine

From a simple naked group handle conversion to a full overhaul/upgrade and paint job, I can help you with any custom work – even custom panels, dual-boiler conversions or brew pressure control modifications, if you’ve got the vision for what you want, I can probably make it happen – depending on whether the result is going to remain functional and safe.

Some examples of custom work:

Again, just give me a call to discuss your ideas and we’ll see what can be done.