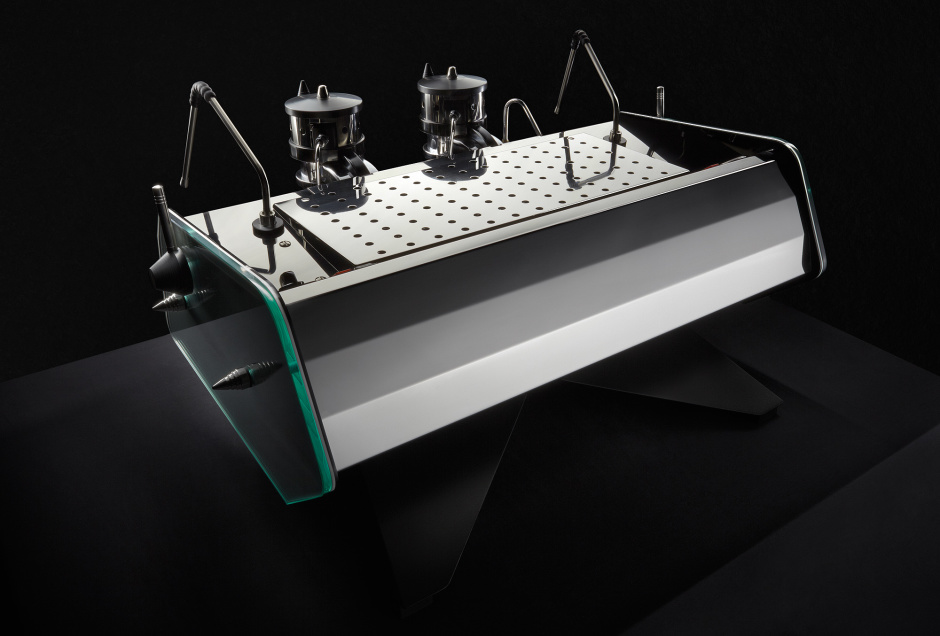

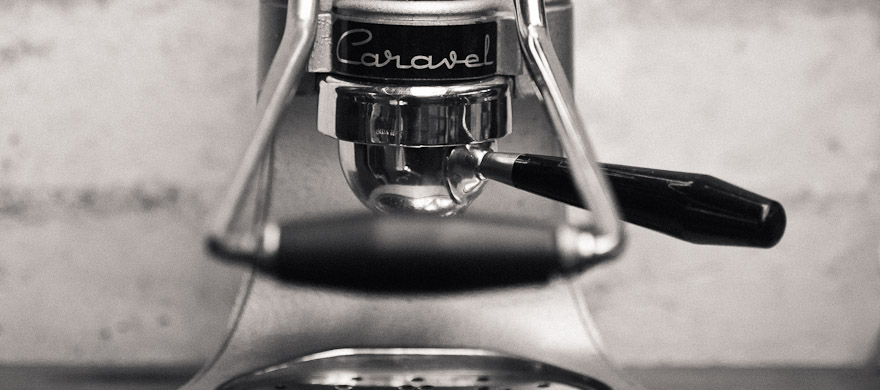

La San Marco single group lever

Posted on January 7th, 2016

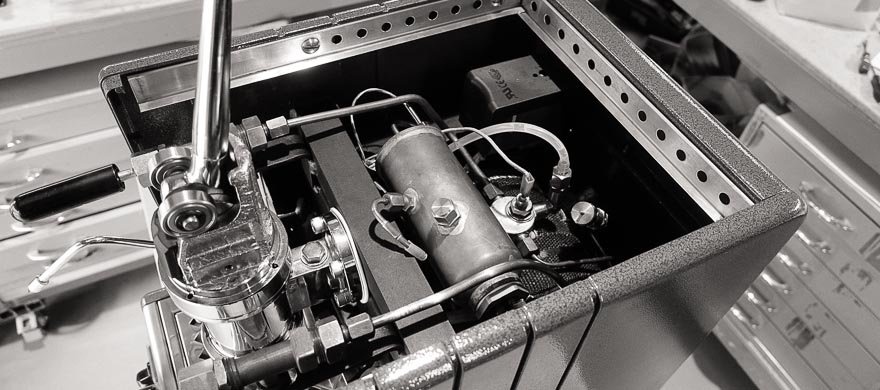

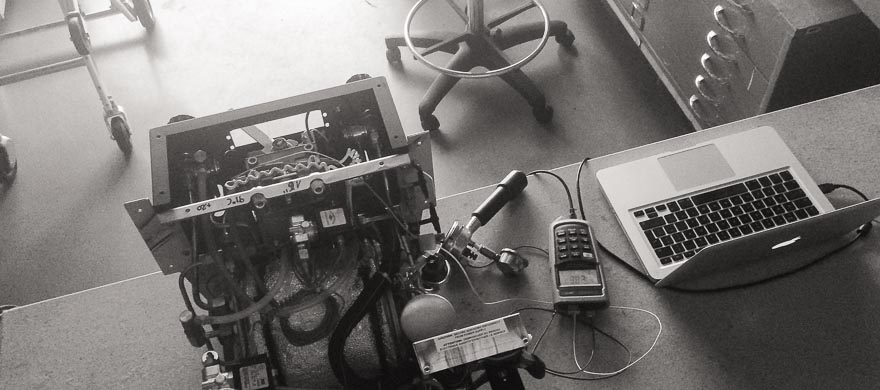

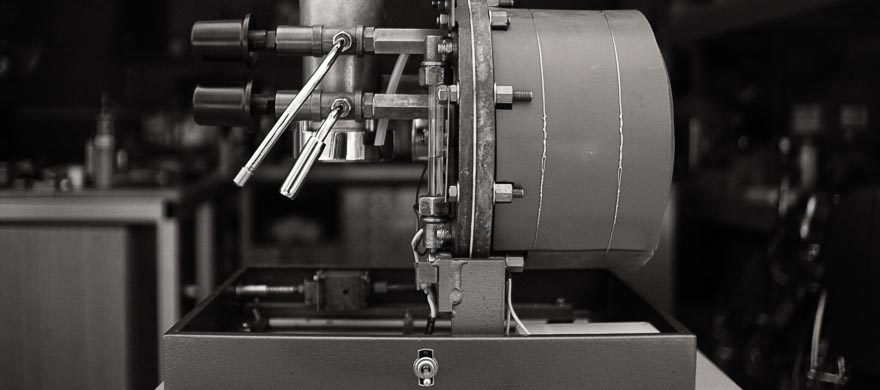

converted La San Marco single group lever

Dual boiler, dual PID commercial lever beast!

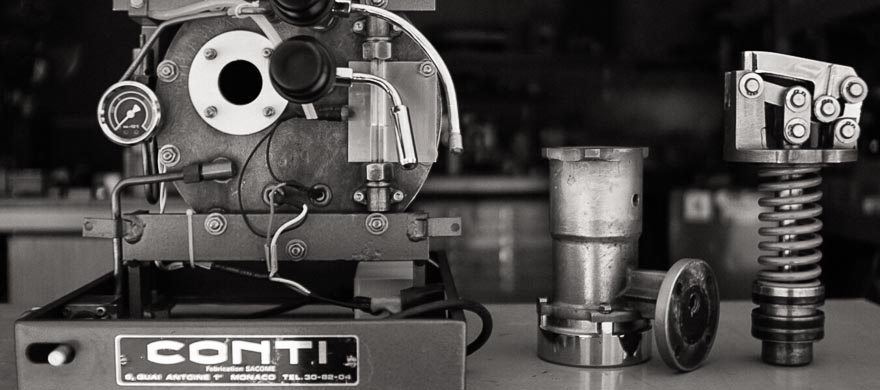

This beast started out life as a La San Marco 85 series, single group volumetric heat exchanger. I bought it last year as a fixer upper, the boiler was over filling and it needed a general going over. 9 months or so later and it’s a very different machine to the one that came in!

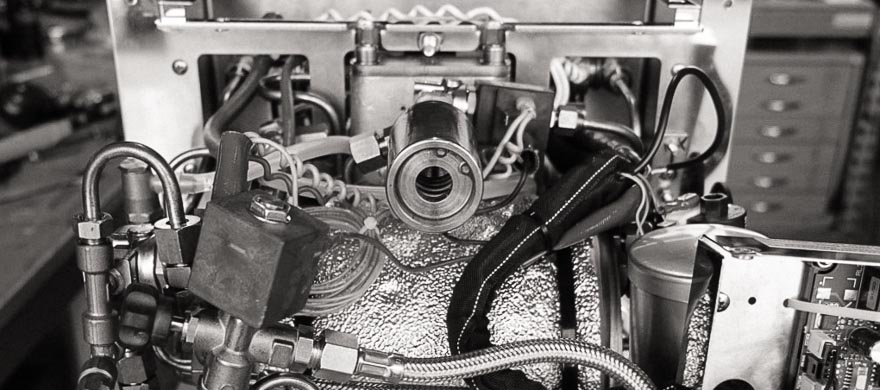

Turns out the over filling problem was a fractured heat exchanger, so that ruled out keeping the machine conventional – the heat exchanger would have to be decommissioned, capped off and become part of the steam boiler volume – I didn’t like the chances of a successful repair.

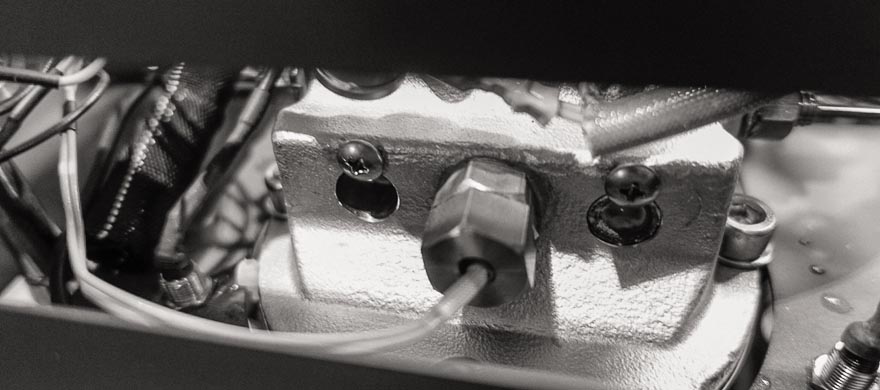

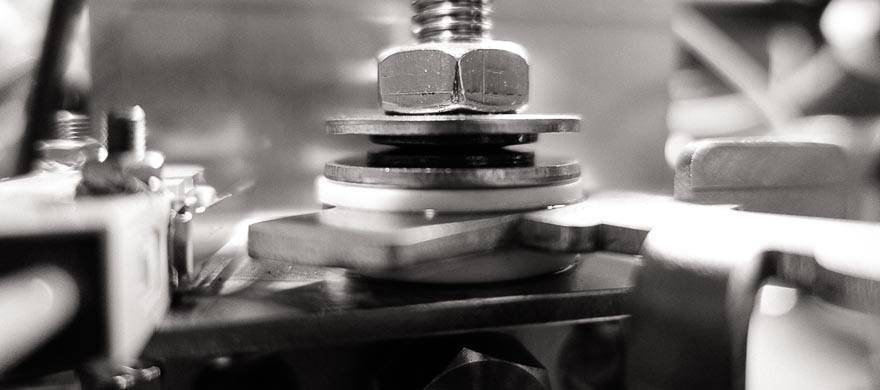

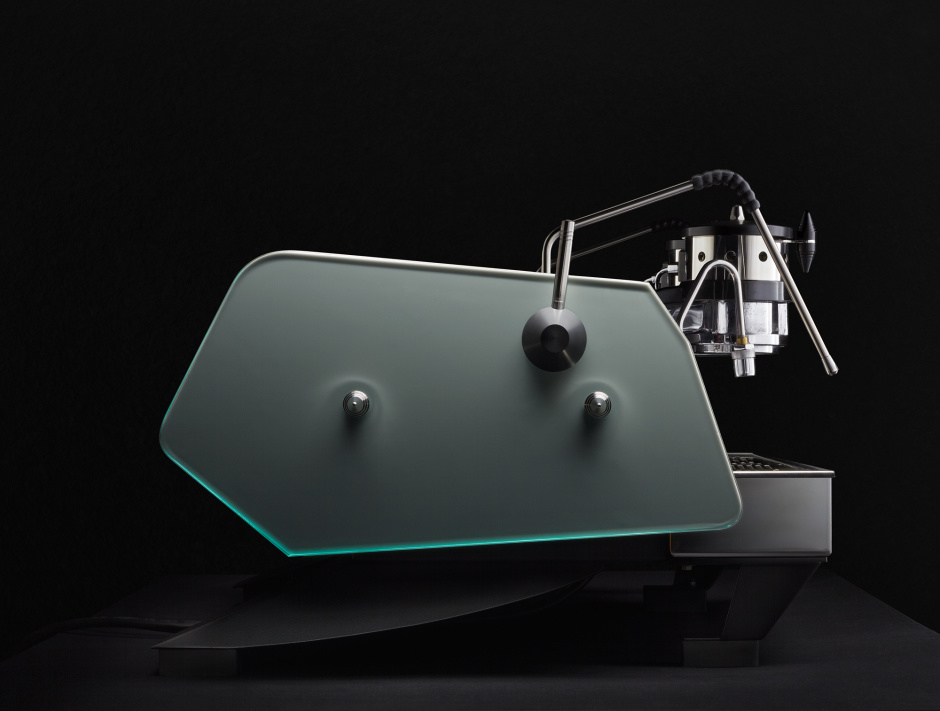

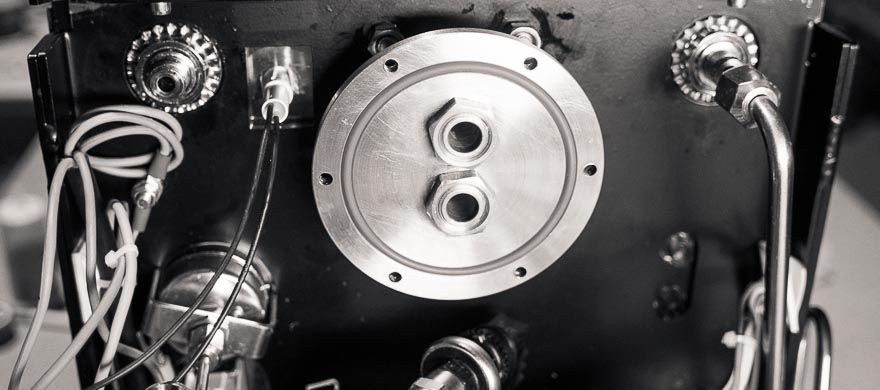

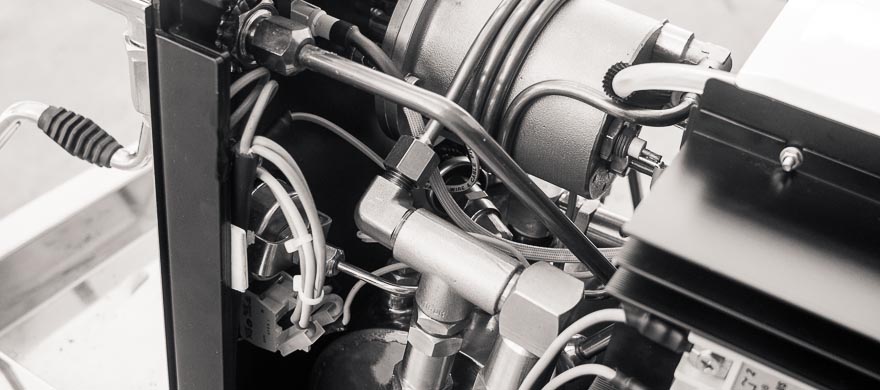

At that point it became a total strip down, and while I had the bare chassis on the bench, I started playing around with the possibility of fitting a lever group that I had spare. With an extra cross member in the chassis, it would totally work! So, off to see my mate Gonz who worked his magic and welded in a cross piece to take half the group flange. The group was already fitted with cartridge heaters, from back in the days of the Quick Mill Achille testing with Talk Coffee, so why not take advantage of that? Then, why not add some extra precision with a dedicated brew boiler as well? Yep, it would fit with a bit of wrangling. I also adapted a small volume heat exchanger into the existing steam boiler to provide pre-heated water to the brew boiler. Serious overkill at this point but why the heck not?!

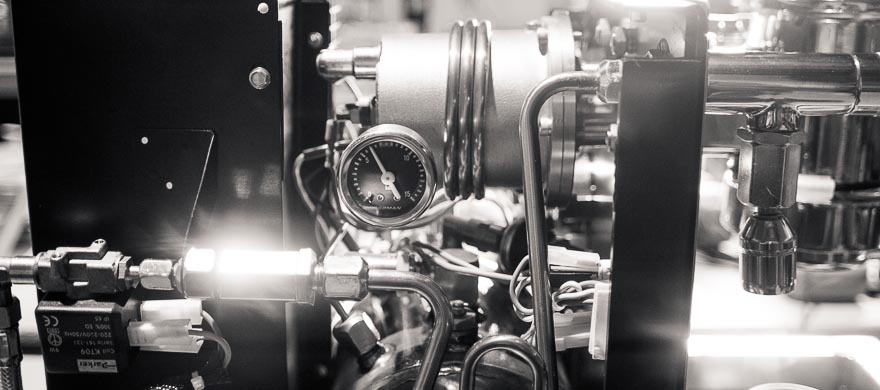

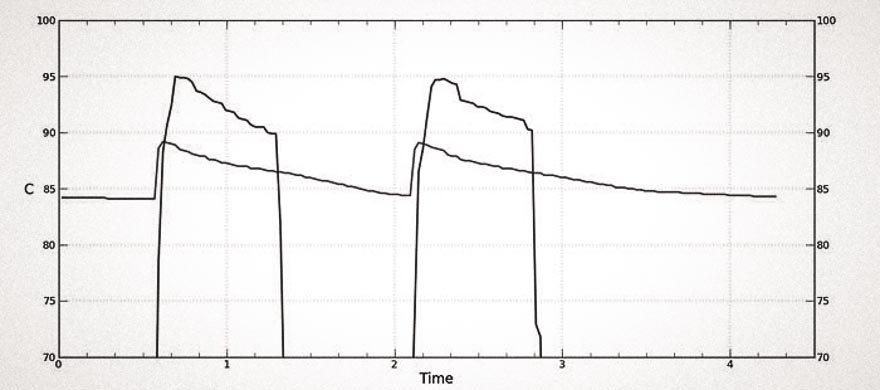

So, this ended up being the most advanced lever machine I’ve built to date, with a PID controlling the group and a PID controlling a dedicated brew boiler just behind it, temperature control is phenomenal. By tweaking the two set points, you can even control the shape of the traditional lever temperature profile.

The original boiler is slightly under-specced at 1700W, but it allows the total machine wattage to stay at approx. 10 amp draw, with 600W in the brew boiler and 200 in the group. It takes a while to reach 1.5 bar, the group is hot well before then – but is ready to go after 25 min approx. and steam pressure is never an issue due to the huge volume for a single group, and added insulation.

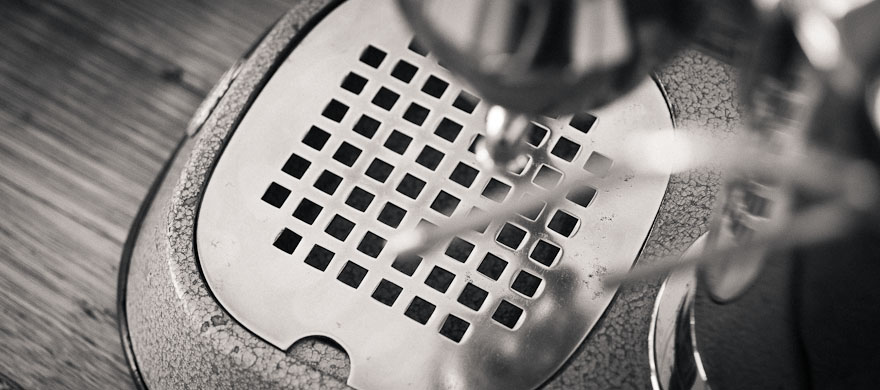

It’s plumbed in only, as the line pressure primes the brewing circuit and is used for pre-infusion. The spring installed in the group (new of course) generates 10 bar peak pressure. It’s a delight to use and pulls wonderful shots. I’m mad to sell it, but that’s the reality of running a business, I can’t hang on to everything!

Summary of work done:

- solved issue with heat exchanger crack

- entirely new brewing system – group, boiler, pre-heater, PID control X2.

- new autofill controller, SSRs, wiring as required.

- rebuilt all existing valves, plumbing.

- powdercoat exterior panels in electric blue hammertone (bold, I know, but it looks stunning!)

It’s probably the most advanced lever machine in the world, in terms of temperature control (at the time of writing – 2016). Offers will be considered. I am in the process of finalising fitment of the front panel, as it was never intended to cover a lever group. Once that’s done she’s ready to go, will not take me long!