Linea Mini paddle modification

Posted on January 6th, 2016

La Marzocco Linea Mini paddle modification

enabling the true function of the Manual Paddle

As usual, there are aspects of any piece of equipment that can be improved. My main gripe with the Linea Mini is that as standard, the paddle switch is not a ‘real’ paddle switch.

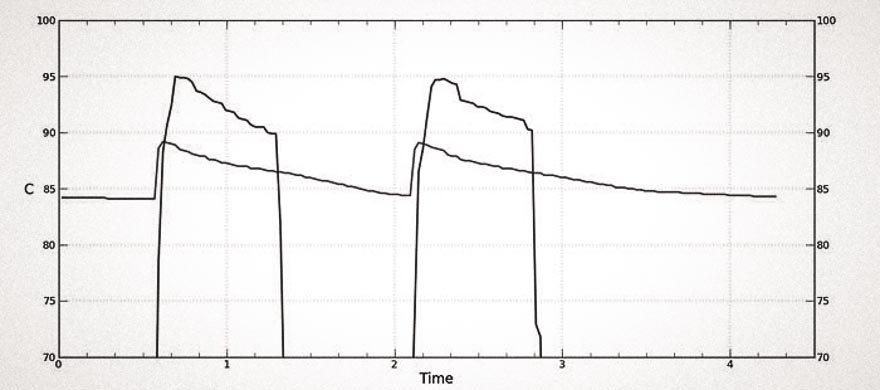

Let me explain – the original MP ‘mechanical paddle’ group is much loved by baristas for the control it allows over the pre-infusion phase of espresso brewing. The mechanical nature of the group allows the water flow to be turned on first at a lower, or ‘line’ pressure – this is simply the water pressure present in the mains and through the boiler/group, usually around 3 Bar. When the paddle reaches the end of it’s travel, the pump is engaged, and full brewing pressure (around 9 bar) is applied to the coffee. This two stage operation allows a skilled barista to perfect each shot by allowing the most critical first stage, where we want an even saturation of the coffee bed, to happen at a lower pressure. This improves the chances of the coffee puck saturating evenly, giving us a tastier shot.

So, a Mechanical Paddle group is a good thing in terms of control, but, being mechanical, there is a down side. It’s relatively complex to make and thus expensive, and, requires fairly regular replacement of o-ring seals. La Marzocco chose to fit a paddle switch to the Linea Mini, but the important distinction here is that it does not operate a mechanical valve, but a single microswitch which engages the water flow and the pump, practically simultaneously. Thus, the ethos of the paddle is lost because there is no first stage. It doesn’t matter how you move it, quickly or slowly, the result is the same. All this is not to say that it doesn’t work – clearly it does, and well, we just lose out on control over the infusion process. Perhaps La Marzocco chose this for reasons of simplicity – my argument would be all well and good, but if there is a paddle switch present, the expectation is that it works like a real one.

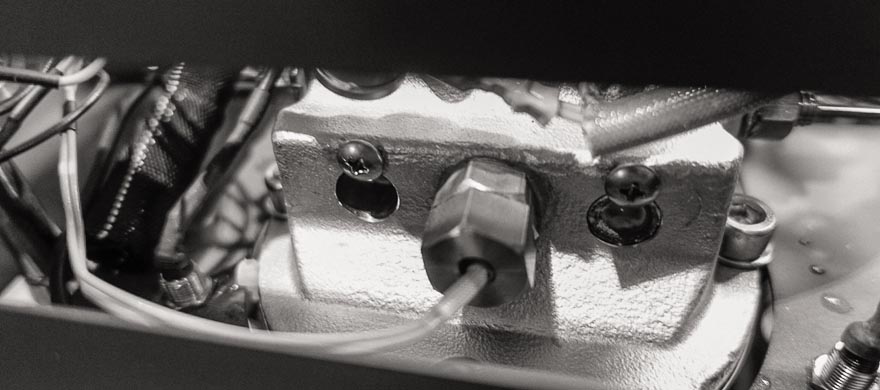

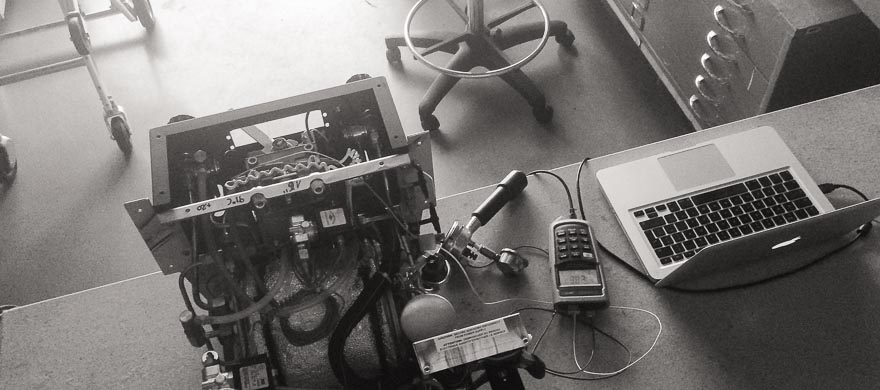

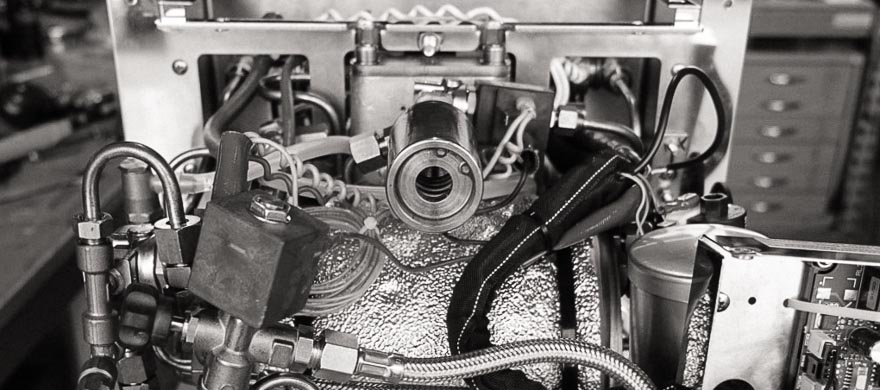

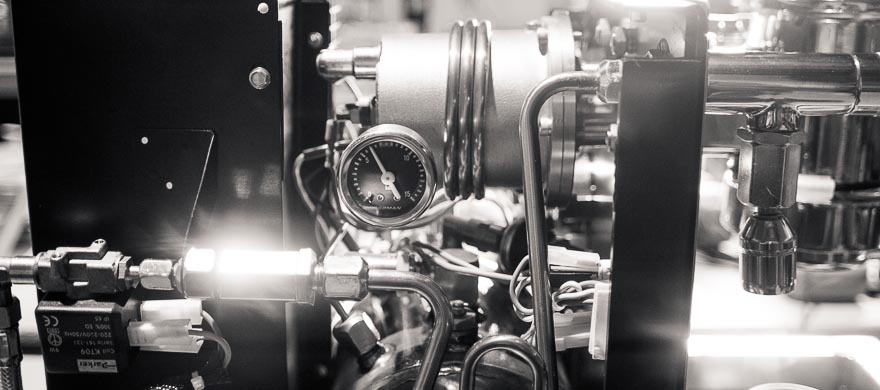

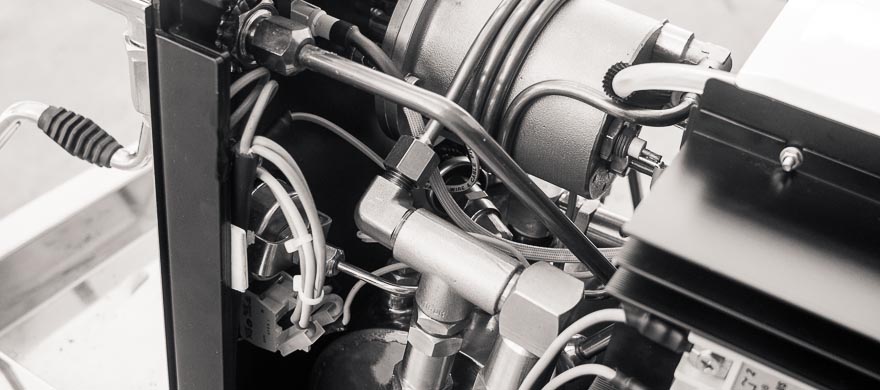

Well, we can make that happen! On the pump outlet I’ve added an extra solenoid with an adjustable needle valve, that is switched on as soon as the paddle is out of it’s stop position. This allows the first stage of the paddle’s movement to replicate the line pressure stage of a mechanical paddle group. In fact, the pressure can be set internally by adjusting the needle valve setting to give whatever pressure is desired for the pre-infusion phase.

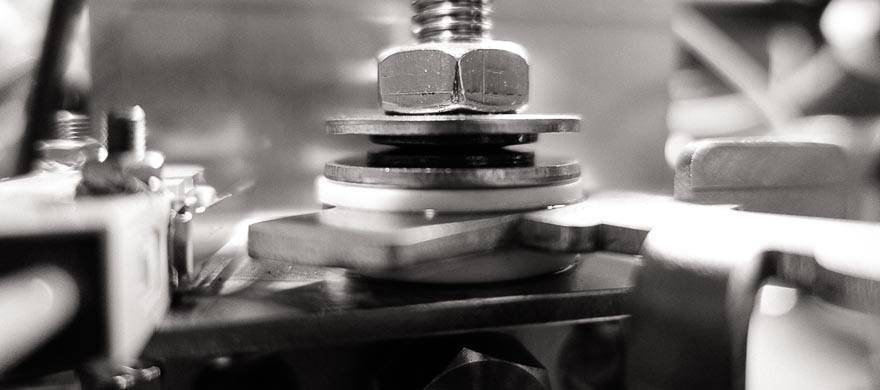

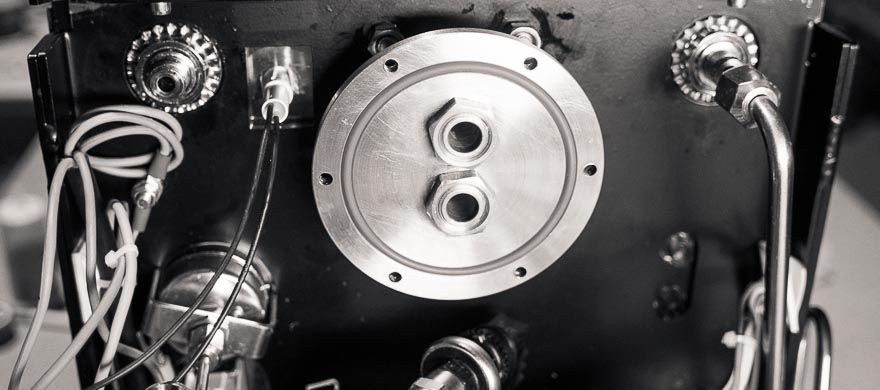

Then when the standard microswitch is engaged mid-way through the travel, the bypass solenoid is switched off and the pump comes to full pressure. In addition I’ve added a spring loaded pre-infusion cylinder to the group to further soften out the pressure ramp-up and decline. The group pressure control ends up being a hybrid of Slayer, Kees van der Westen Speedster and La Marzocco Mechanical Paddle – with the best of all worlds. All electric, no seals to replace and fully adjustable. I’m very happy with the result!

Summary of the modification:

- two-stage operation with adjustable ‘line’ pressure

- spring-loaded chamber further smooths out pressure ramp-up

- All electric, no seals to wear out

- works in tank mode or plumbed in, with adjustment of needle valve accordingly

- hybrid of Slayer, Speedster and La Marzocco pre-infusion systems

- paddle action refined for perfect smoothness and feel

At this stage the installed modification is only available for machines brought to my workshop, and there are no plans to distribute a kit as modifications of factory parts, plumbing and electrical connections are required. If you are confident to handle this work as a DIY install, please contact me for pricing and availability. Alternatively you could contact a trusted technician local to you to perform the install work with my instructions. The modification is available for both 230V and 110V machines.