Repairs and servicing

Posted on September 21st, 2012

Repairs and servicing

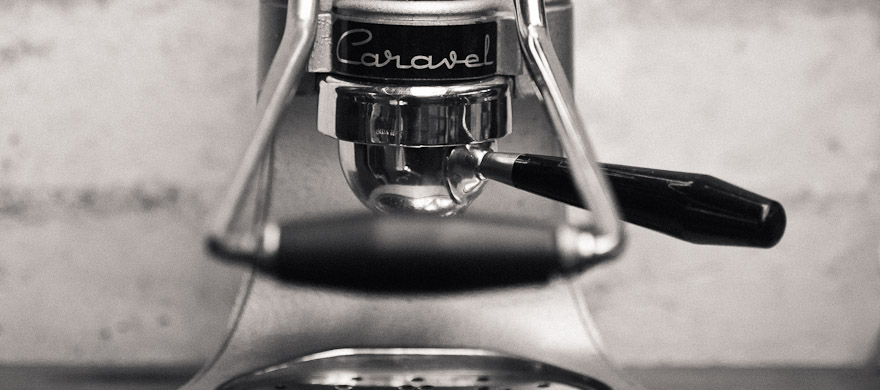

Keeping you extracting – commercial or domestic

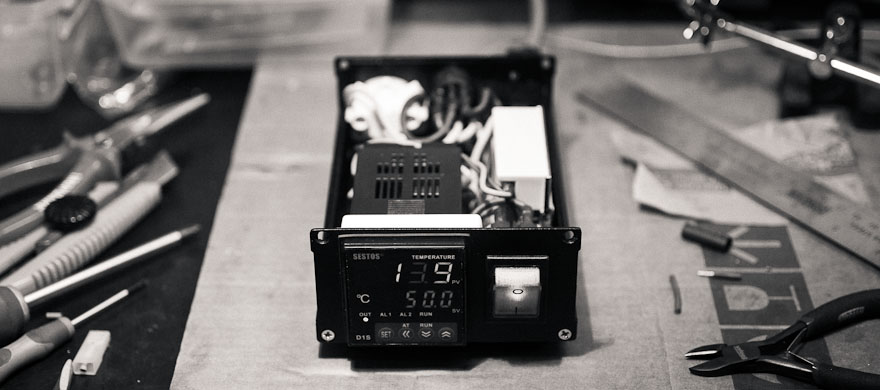

Repairs and servicing are what I spend most of my waking hours on. When things aren’t working as they should, you need the problem rectified quickly so you can keep enjoying your equipment. With many years of experience working on all brands of commercial and domestic espresso equipment, I’ll ensure that you’re back up and running with the minimum of fuss – whether it’s as simple as changing a filter or adjusting pump pressure, right through to a major breakdown.

You’ll also get the kind of personal service and attention to detail that you can only expect from a dedicated individual. I want you to be happy with my work, and I’ll take the time to make sure that you are. Crucial to that is that I don’t just know machines, I know coffee and I can have a conversation with you about how different parameters in the machine affect the results, and look at your whole system including the machine, grinder, coffee and water source to identify issues that may not have been readily apparent.

For domestic equipment, if you are dropping off at my Northcote workshop location I aim for a 48 hr turnaround. Otherwise, an on-site call may be required if the equipment is hard to move, or in commercial use. See the FAQ page for more details.

For commercial clients, if it’s not a breakdown I’ll work with you to attend at a time that suits your business. The last thing you want is to be turning customers away because your machine’s out of action.