James’ San Marino

Posted on December 2nd, 2012

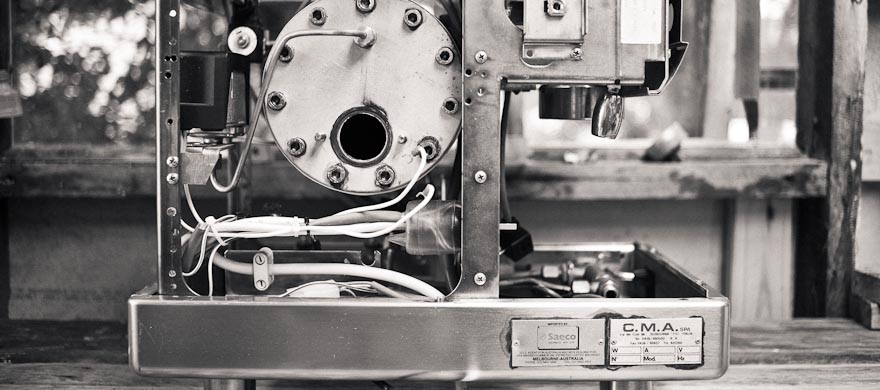

James’ San Marino

Commercial single-group machine

I can’t think of a machine with a worse reputation in the industry than the San Marino but I kind of like them, and machines made by CMA in general (wega, astoria etc). They’re solid, no-nonsense commercial workhorses that may not be sophisticated, but dangit they get the job done. James loves his, and it’s been on coffee duty at his studio for many years. When the element gave up, we decided a thorough overhaul was in order.

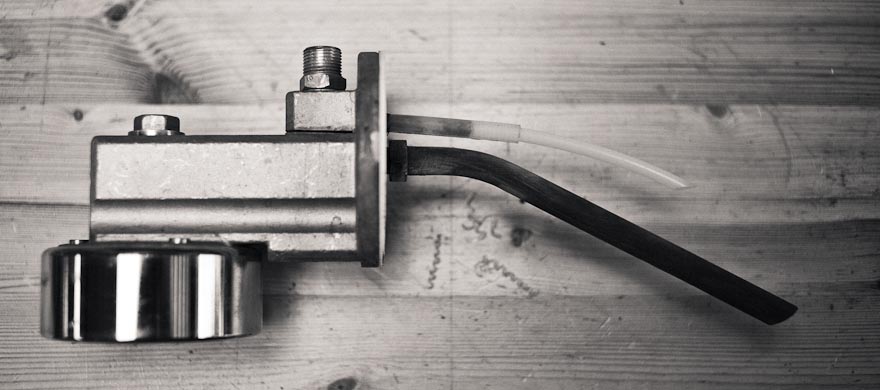

Predictably, I went a bit nuts and decided to see how well I could make it work. The main drawback with San Marinos is that they lack a thermosyphon – the group is bolted to the boiler and can drastically overheat. The solution in this case is to inject cold water deeper into the heat-exchanger to lessen the need for a hot flush right at the start of an extraction. I also wanted to control the flow rate from the group, which was way too high, by fitting a restrictor to the inlet side of the group solenoid. The finishing touch, apart from a thorough recondition of all valves, sight glass, boiler valves etc, was to add a dual rocker switch for the solenoid and pump – allowing manual pre-infusion control via mains pressure.

Summary of improvements:

- Brew water temperature down from +98 degrees c. to 92-94 after a 30 ml flush

- Flow rate down to 600 ml per min from the group for controlled extractions

- variable mains pre-infusion time via independent switching of the solenoid and pump

I was pretty stoked, and James was too –

Many thanks for your all your efforts in resurrecting my San Marino. This machine is at its best and has never worked in this manner ever! As you can see by the lateness of this email – you may guess that I’ve had a couple of long blacks.

Job done!