Custom Salda

Posted on September 21st, 2012

Custom Salda

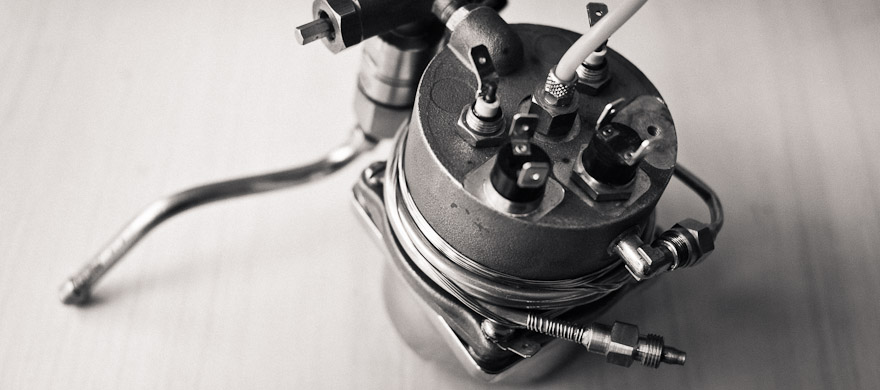

Single boiler domestic machine

I bought this little Salda for $10 at a garage sale, knowing it would be a good little machine with a service and a few minor improvements.

As standard, single boiler machines including the Rancilio Silvia, Gaggia Classic, Lelit, Nemox, Imat, Quaha and others are perfectly capable of making good espresso though with a few downsides, one of which is a huge variance in boiler water temperature due to their very simple thermostats. This can be compensated for in a few ways, one popular option being to retrofit a PID controller to help regulate boiler temperature more precisely, which is one key ingredient to making consistently good espresso.

This is a rather expensive and complicated option (although PID hardware itself is not costly these days – it’s the installation and calibration that can be tricky), and a simpler, more cost-effective modification can be to simply fit a digital thermometer to the boiler giving the user a visual indication of the boiler temperature, which can then be used to time the start of the espresso extraction for the best results. This is known as Temperature Surfing.

Improvements included:

- Replacing the original Saeco-type pressurised portafilter and group collar with a 57mm non-pressurised Lelit type, with naked conversion

- Brew water pre-heating via a simple tube that wraps around the boiler to improve temperature stability

- Digital temperature display via thermocouple fitted to brass boiler

- Conversion to ball-joint steam wand including custom single-hole steam tip

- Brew pressure gauge fitted between 3-way solenoid and group outlet to read true extraction pressure

- Kill switch fitted to pump to enable low pressure pre-infusion

- Custom aluminium handles for steam valve / portafilter, custom Huon Pine matching tamper

I ended up taking things a bit further than I’d initially planned, but I reckon this is now the best little single boiler machine around, and makes killer shots with a bit of careful attention to the brewing temperature and pressure. As it’s so simple and small, this is the perfect machine to chuck in the boot with a hand grinder for a weekend away.