Andy’s Londinium

Posted on August 9th, 2013

Andy’s Londinium

Domestic lever dual boiler conversion

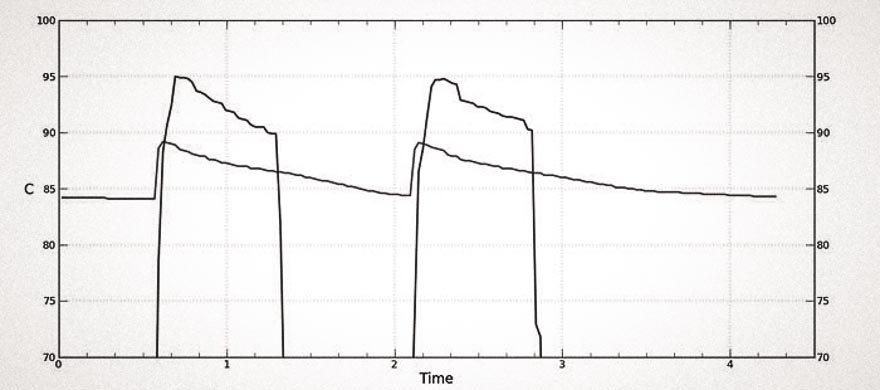

The Londinium Espresso L1 is a new addition to the market for single group lever machines intended for domestic use. There has been a recent resurgence of interest in lever espresso machines, as we are finding out more about the subject of ‘pressure profiling’, or controlling the water pressure applied to the coffee puck at different stages of the extraction.

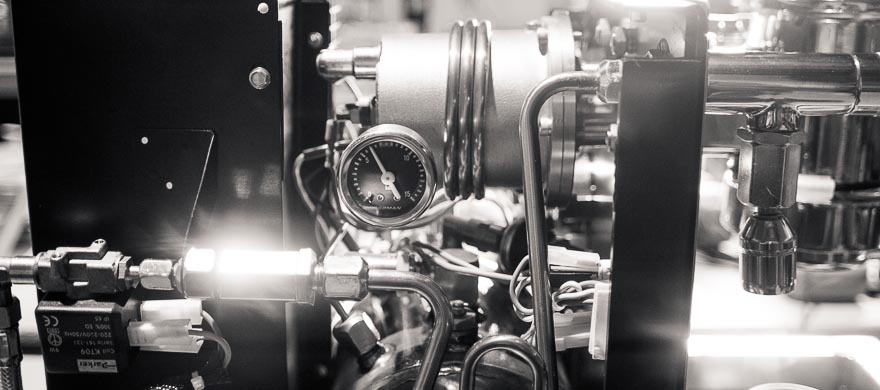

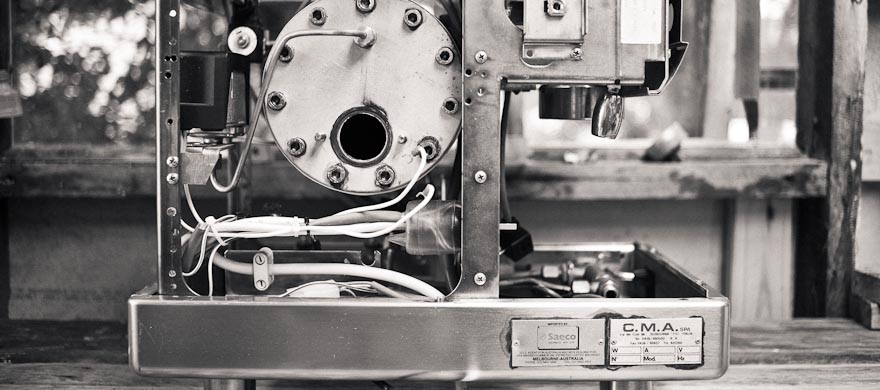

Andy was a little disappointed with both the fit and finish and the temperature stability of the machine, so we decided to see what we could do to take it to the next level. Without going into too much detail, the Londinium uses a fairly uncommon thermosyphon arrangement to get enough heat into the massive group. After gathering some data on how the thermosyphon functions and comparing this with other user’s data from around the world, it appears that there are conditions that can alter it’s performance, resulting in low group temperatures and sour shots.

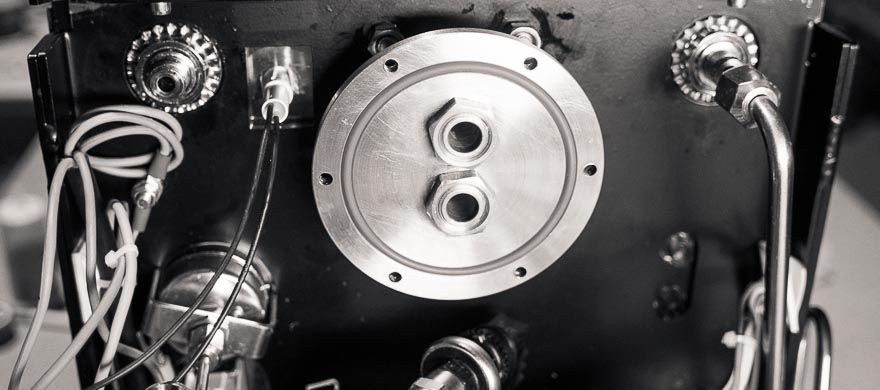

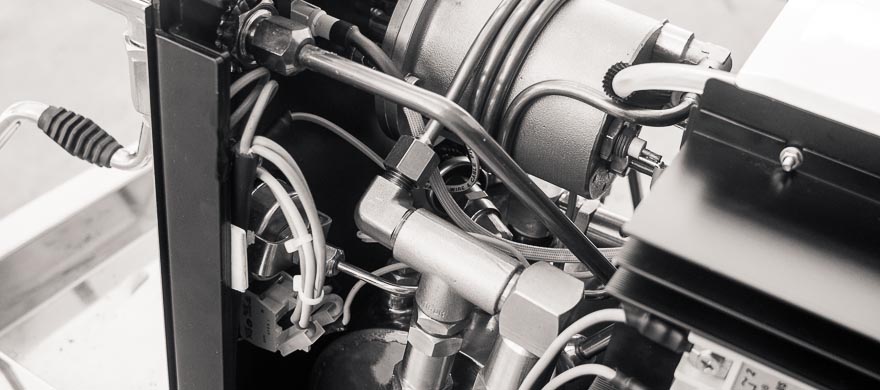

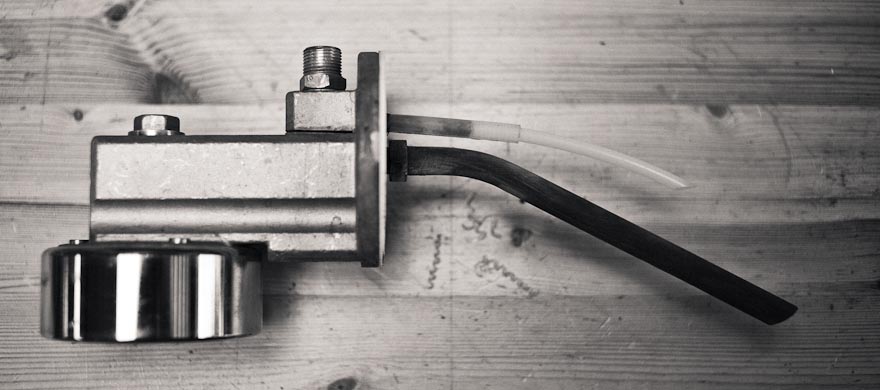

We considered a few options, one of which was reconfiguring the thermosyphon into a true heat exchanger that operated from mains water pressure instead of the built-in tank, but Andy was keen to retain the ability to run from tank. This meant a drastic alteration of how the group was heated, and the fabrication of a separate brewing boiler to tightly control the water temperature at the group. Luckily, the internal construction meant that the original boiler could be retained and minimal alterations to the layout were required.

The end result is a traditional lever machine that has all the inherent temperature controls of a modern dual boiler machine. Changing the set temperature of the brew boiler controller results in a quick change in the idle temperature of the group itself, which governs the temperature profile of the shot.

We were also able to address a few of the annoyances with machine fit and finish, such as ease of emptying the drip tray, placement of switches and internal venting of the anti-vacuum valve.

Andy is stoked, and the proud owner of what may be the most technically advanced lever machine in the world.